Our sustainable technology

An innovative process

We design and manufacture smart dry paint films.

They save time, integrate additional functions, and respect the people who use them and the environment.

The 6 key steps of our technology

1 | Use of paint as a raw material

We adapt ourselves to our customers by using acrylic, epoxy, polyurethane paint or formulating specific paint.

2 | Transformation of liquid paint into flexible films

We transform the paint into a multi-layer system with a thickness of 17 to 500 μm. Controlling thickness is a key factor for robustness.

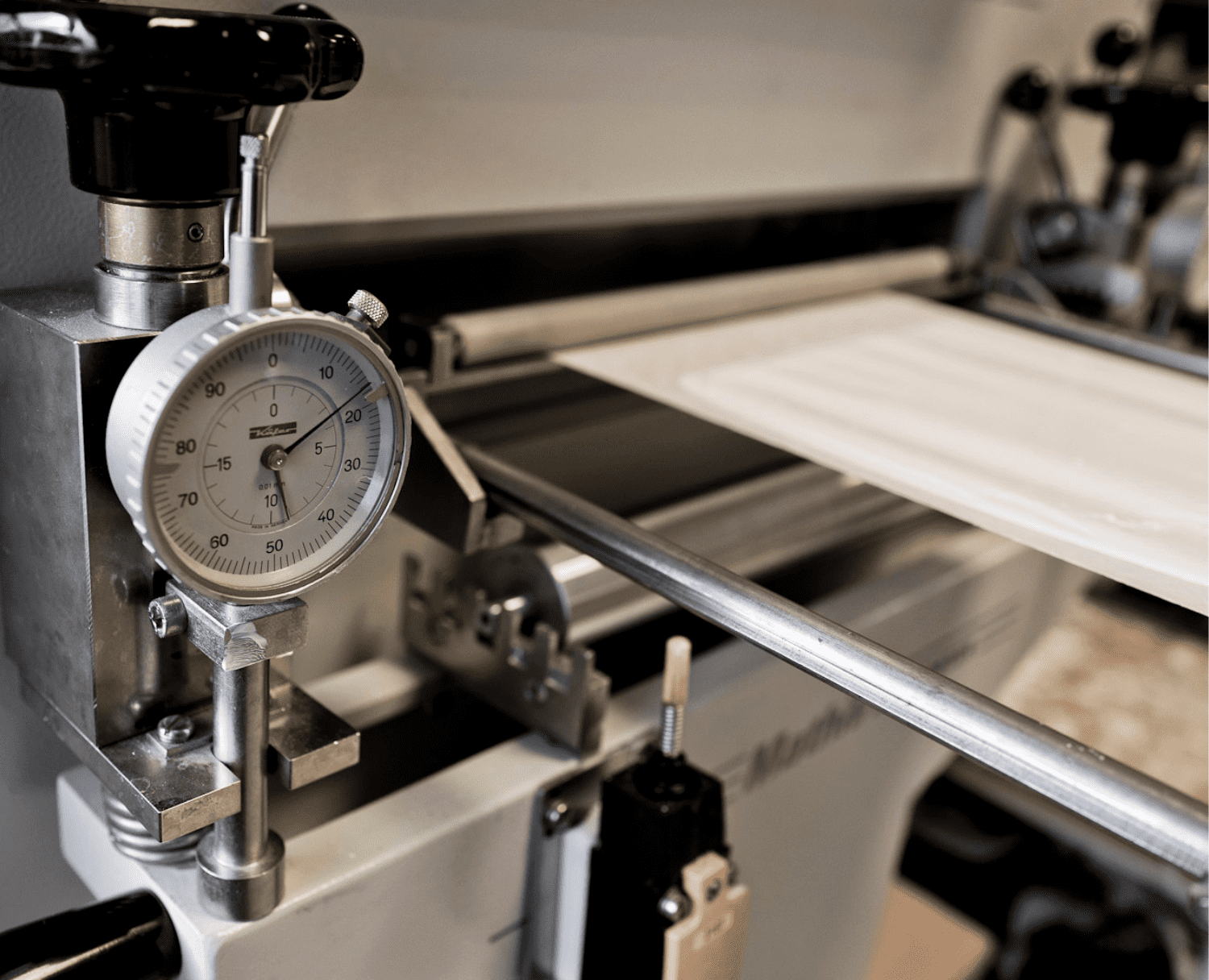

3 | Quality control

We check the thickness of each layer of the film and identify any defects, to insure required quality standards.

4 | Complexing

We add components to the film (glass veil, protector, adhesive, bronze mesh, etc.) depending on the applications.

5 | Cutting into coils

We package flexible paint films according to the needs of our customers. The coils have a width of 730 to 2500 mm and a length of 30 to several hundred meters.

6 | Audit and packaging

We inspect products before packaging and dispose of defective systems.

Why is our technology responsible ?

It consumes little water during application

It respects users and their health

It reduces vapors due to the drying phases

It lasts over time

It will eventually become recyclable

Get in touch

Do you have a question?

Please leave us a message!

Corso Magenta collects and processes your personal data to better respond to your requests. Learn more about how we manage your data and your rights.

Want to contact us another way ?

+33 (0)1 85 78 45 40

22-24, rue Lavoisier, Bâtiment A

92000 Nanterre

France